Now is a great time for c-store technology, said Tyler Grubbs, executive director of digital and store technology at RaceTrac during a panel at the National Retail Federation show in New York City earlier this year.

He noted that the convenience retail industry has long suffered from a lack of tech innovation, but changing attitudes have shifted the paradigm over the past three to four years.

“I think the industry said enough's enough, and really has put their money where their mouth is and invested in partners and technologies to change the paradigm,” he said during the panel on smart technology.

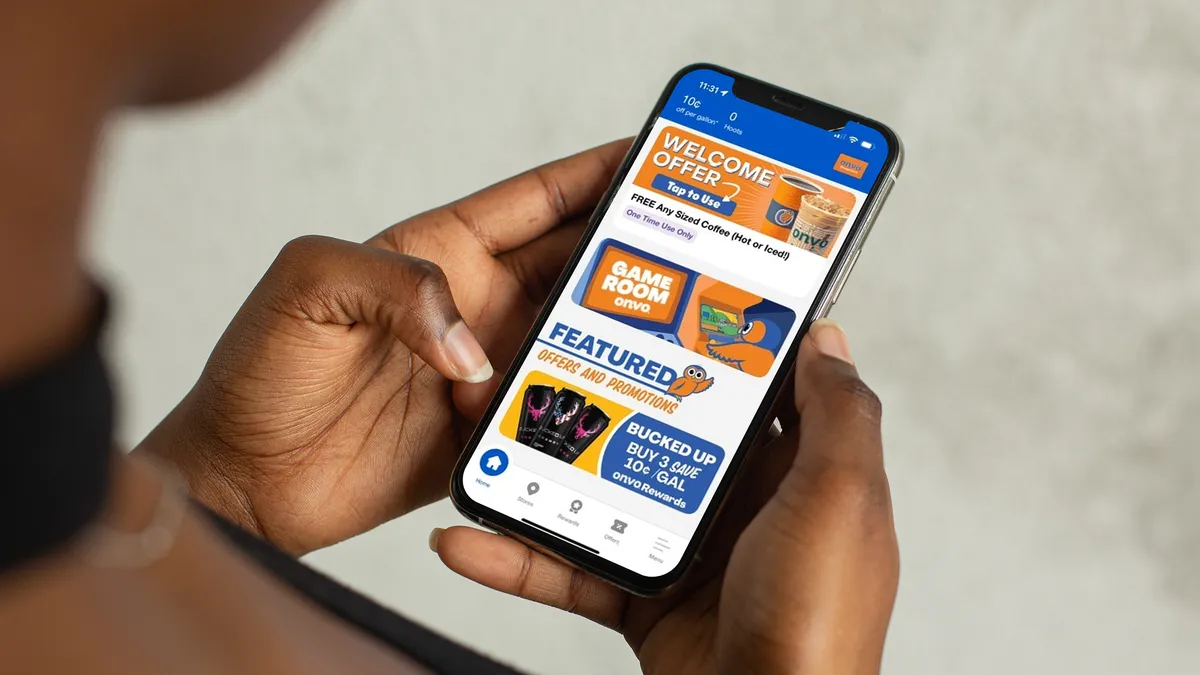

In just the past year, Atlanta-based RaceTrac added technology partners across a number of areas, including supply chain, temperature monitoring and forecourt equipment. It also updated its mobile app.

And while the retailer has already made great strides, it continues looking for more technology that addresses needs and improves operations.

“Our hope is that if we enable the right technology foundation, we are going to be able to scale quickly,” Grubb said.

Big boost at the fuel pumps

Four years ago, RaceTrac had no way of knowing how many fuel pumps across its footprint were malfunctioning at any given time. Worse, the way they found out was usually from a frustrated guest alerting them. Then someone at that store would need to manually create a service ticket.

That process “hit the trifecta” of problems — inconveniencing a guest, putting more work on an employee and potentially costing sales.

RaceTrac tested a number of solutions to address this over the past few years, and eventually adopted technology that provided real-time monitoring of all of its pumps.

The first thing RaceTrac’s leaders learned from that monitoring is that the number of pumps needing attention was usually higher than they thought.

“We thought two and a half to three and a half percent of our pumps were down at any point in time.” said Grubb. “Turns out it was more like six and a half [or] seven.”

In some cases, the new tech can pinpoint exactly what part of the pump isn’t working. In others, it just flags that there is an issue. The system can automatically generate maintenance tickets about 75% of the time, and identifies which problems can be fixed remotely, resulting in fewer maintenance dispatches.

These improvements have not only saved money, but drastically improved pump uptime.

“We're now at a point where we've got about 0.3% of our pumps down at any point in time,” said Grubb.

Happier workers, happier customers

Grubb also said that a better employee experience can help c-stores address high front-line turnover. Cycling through new hires puts more pressure on managers, who are spending more time training team members than doing their other tasks. This can frustrate managers and eventually “create a death spiral inside that operational environment,” Grubb explained

RaceTrac has integrated training technology that doesn’t rely as much on up-front training, instead “showing [workers] in the moment” what they need to do and how to do it. This ranges from telling them what goes into a specific food order to reminding them of store policies.

“You give it to them right in the moment,” Grubb said. “And then you can build on that over time and then move into more advanced trainings.”

Making their job easier can increase employee satisfaction and retention, as well as improve training and store operations, “which will ultimately translate into a better experience for our guests, so that we can drive loyalty,” Grubbs said.

This new training technology isn’t just aimed at making things less stressful for workers. It’s also about achieving specific benefits like higher accuracy and faster ordering times.

When implementing any new technology, Grubb said it’s important to establish “clear measures of success” that make it easier to evaluate if a product or program is doing its job.

Getting it right

RaceTrac has also worked to change how team members think about new technology. Grubb said that in the past, team members might suggest a product because it had a specific feature they wanted. Now, they’re sharing their needs with the tech department, which can evaluate options and propose solutions that fit better into the company’s overall plan.

“[These solutions] may not be sexy,” said Grubb. “Back loading an invoice is not sexy, but when you do it 3 million times a year at 75 data points an invoice, it's a lot of key-in that you don't have to do anymore.”

He added that focusing on a specific feature for a tech solution doesn't always align with the organization’s needs.

“Really it was our own internal processes that didn't set the tool or the vendor or the capability up for success,” he said.

Some of RaceTrac’s answers remain simpler for now. For instance, Grubb noted that the company’s bean-to-cup coffee machines can’t send specific alerts when something goes wrong, but they do have smart plugs, which record the power spikes when the grinder is in use, offering Grubb and his team some indication of uptime.

“I don't see that [energy spike] for two days, I’ve probably got a problem, right?” Grubb asked

As RaceTrac expands its technology, Grubb said his ambition is “to turn every action that happens in the store into a structured data point” from the time a customer walks in to the time they walk out.

“Turn that into a data point, and I know we will find the use cases for it.”